Concrete Hollow Block with Reused Glass

Main Article Content

Abstract

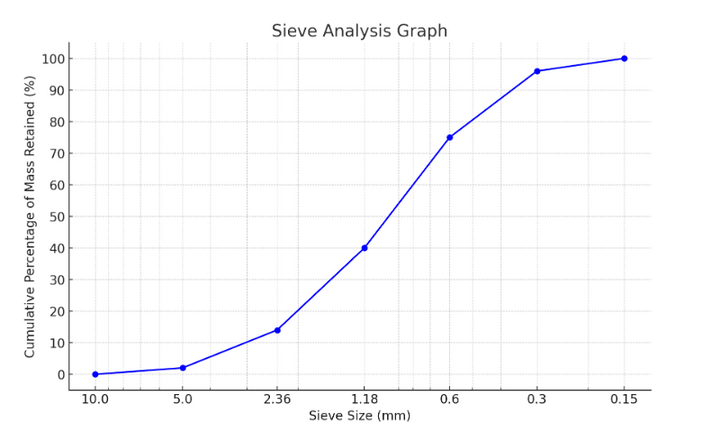

Concrete is being used a lot in construction. As urbanization accelerates globally, the demand for sustainable construction materials is becoming increasingly critical. Traditional concrete, a staple in the construction industry, is known for its environmental impact due to high energy consumption in production and the extensive use of natural resources. In response to these concerns, researchers and industry practitioners are exploring innovative approaches to enhance the sustainability of construction materials. One promising area of investigation is the incorporation of recycled materials into concrete mixtures. In this study, we aimed to determine the level of glass replacement resulting in optimal compressive strength. The objectives of this study are to produce a concrete hollow block with reused glass and to find out whether the reused glass can be used as partial replacement for aggregates. Three concrete samples were tested at 7, 14 and 28 days for glass replacement proportions of 10%, 15% and 20%. Based on its maximum load at failure, 10% of reused glass substitution is applicable for interior wall. The hollow concrete produced by using 10% of reused glass with sized 320cmx180cmx180cm.

Downloads Statistics

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

References

British Standard Institution (2013). Aggregates for concrete. United Kingdom: BS EN 12620.

British Standards Institution (2009). Testing fresh concrete– Part 2: Slump test. United Kingdom: BS EN 12350-2.

British Standards Institution (1983). Testing fresh concrete– Part 111: Method of normal curing of test specimens (20 °C method). United Kingdom: BS EN 1881-111.

BS 1881-122:2011 Part 122: Method for determination of water absorption

British Standards Institution (1983). Testing concrete– Part116: method for determination of compressive strength of concrete cubes. United Kingdom: BS 1881-116:1983.

MS EN 1991-1-1:2021 Eurocode 2-Part 1-1: Design of concrete structure- General rules and rules for buildings, Department of Standards Malaysia

Kumari, P., Sajad, D., Bhat, A., & Goyal, Y. (2020). Effect of replacement of fine and coarse aggregate by sawdust in solid concrete blocks for different mix proportions

Oyedepo, O. J., Daniel, S., Sunmbo, O., & Akande, P. (n.d.). (November 2022).Investigation of properties of concrete using sawdust as partial replacement for sand.

Mama, C. N., Nnaji, C. C., Onovo, C. J., & Nwosu, I. D. (2019). Effects of Water Quality on Strength Properties of Concrete. International Journal of Civil, Mechanical and Energy Science, 5(2), 7–13. https://doi.org/10.22161/ijcmes.5.2.2

PDF

PDF

https://doi.org/10.32487/nuce.v3i1.605

https://doi.org/10.32487/nuce.v3i1.605